Beyond Standard: Custom LiFePO4 Battery Packs Designed for Your Unique Project Challenges

Struggling to find a battery solution that fits your project’s exact needs? Off-the-shelf options often fall short, leaving you with compromised performance or unnecessary costs.

Custom LiFePO4 battery packs1 are tailored to your project’s voltage, capacity, and form factor requirements, ensuring optimal performance, longevity, and cost-efficiency for specialized applications.

Every project has unique power demands, and a one-size-fits-all approach rarely works. Whether you’re building an electric vehicle, a solar storage system, or a marine application, custom LiFePO4 battery packs provide the precision and reliability you need.

From Concept to Casing: Expert LiFePO4 Battery Pack Customization for Optimal Performance

Ever wondered how a custom battery pack goes from a sketch to a fully functional power solution?

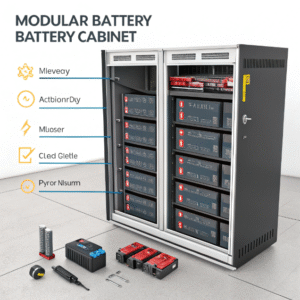

Custom LiFePO4 battery packs are engineered from the ground up, integrating precise cell selection, advanced BMS (Battery Management System2) configurations, and rugged enclosures to meet your project’s specific performance and environmental demands.

Step-by-Step Customization Process

-

Requirements Analysis

- Voltage, capacity, and discharge rate are calculated based on your application.

- Environmental factors (temperature, vibration, moisture) are assessed.

-

Cell Selection & Configuration

- High-quality LiFePO4 cells are chosen for their safety and longevity.

- Series/parallel arrangements are designed to meet voltage and capacity needs.

-

BMS Integration

- A tailored BMS ensures protection against overcharge, over-discharge, and short circuits.

- Features like cell balancing and thermal monitoring are added as needed.

-

Mechanical Design

- Enclosures are designed for durability, weight efficiency, and ease of installation.

- Custom connectors and wiring harnesses simplify integration.

| Customization Aspect | Benefit |

|---|---|

| Cell Configuration | Matches exact power needs |

| BMS Features | Enhances safety and lifespan |

| Enclosure Design | Ensures durability in harsh conditions |

Built to Spec, Built for Reliability: Your Trusted Partner for Custom LiFePO4 Battery Packs

Why settle for generic batteries when you can have a pack designed for reliability?

Partnering with an experienced manufacturer ensures your custom LiFePO4 battery pack is built with premium components, rigorous testing, and adherence to industry standards, delivering unmatched reliability for critical applications.

Why Expertise Matters

- Quality Components: Only top-tier LiFePO4 cells and robust BMS units are used.

- Testing Protocols: Each pack undergoes cycle testing3, thermal stress tests, and safety checks.

- Compliance: Meets UN38.3, IEC, and other relevant certifications.

Case Study: A marine application required a waterproof, high-capacity battery pack. The custom solution featured an IP67 enclosure, marine-grade wiring4, and a BMS with saltwater corrosion resistance.

Your Blueprint, Our Battery: Seamless Integration with Custom LiFePO4 Pack Manufacturing

Have a design in mind but lack the technical expertise to bring it to life?

We transform your specifications into a fully functional LiFePO4 battery pack, handling everything from prototyping to mass production while ensuring seamless integration5 with your system.

Collaboration Workflow

- Consultation – Discuss your needs, constraints, and goals.

- Prototyping – Develop a working model for validation.

- Production – Scale up with consistent quality control.

- Support – Provide ongoing maintenance and troubleshooting.

Example: An EV startup needed a lightweight, high-energy-density pack. We optimized cell arrangement and cooling, reducing weight by 15% without sacrificing range.

Conclusion

Custom LiFePO4 battery packs deliver precision, reliability, and efficiency, ensuring your project performs at its best without compromise.

Explore the advantages of custom battery packs tailored to your specific project needs for optimal performance. ↩

Learn how a BMS can protect your battery and improve its lifespan through advanced features. ↩

Understand the significance of rigorous testing protocols in ensuring battery reliability and safety. ↩

Explore the importance of using marine-grade materials for durability and safety in marine applications. ↩

Discover how effective integration processes can enhance the overall functionality of your battery system. ↩