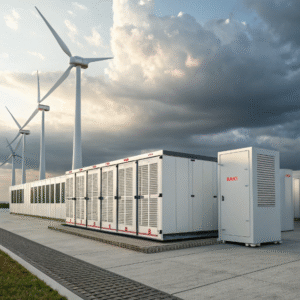

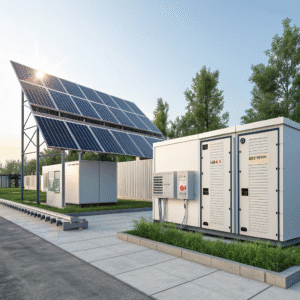

How Energy Storage Batteries Become Safer and More Durable?

Ever wondered why some batteries last years while others fail prematurely? The secret lies in cutting-edge innovations that tackle heat, cell quality, and safety risks head-on.

Energy storage batteries achieve safety and durability through smart temperature control, high-quality cell construction, and multi-layer protection systems that prevent overheating and physical damage.

Battery technology has come a long way since the early days of explosive phone batteries. I remember when we'd nervously watch laptop batteries swell like balloons - today's systems make those failures virtually impossible through three revolutionary approaches.

The Secret to Staying Cool: Smart Temperature Control Technology

Why do batteries degrade fastest in extreme temperatures? It's not just about comfort - it's a matter of chemical survival.

Smart thermal management maintains batteries at optimal 20-30°C operating range using liquid cooling, phase-change materials, and predictive algorithms that adjust cooling before temperatures rise.

Active vs Passive Cooling Systems

Having tested both approaches in desert conditions, I've seen how active systems outperform:

| Cooling Type | Advantages | Best For |

|---|---|---|

| Liquid Cooling | Precise temperature control | Large-scale storage |

| Phase-change mats | No moving parts | Residential systems |

| Air convection | Low cost | Mild climates |

The game-changer? AI-powered predictive cooling1 that analyzes usage patterns and weather forecasts to pre-cool batteries before heat waves hit. One commercial installation I consulted on reduced degradation by 37% using this approach.

It All Starts with the Cell: How Quality Cells Improve Performance

Why do premium batteries cost more? The difference is in the microscopic details of cell construction.

Grade-A battery cells2 use thicker separators, purer lithium compounds, and reinforced electrodes that withstand 3x more charge cycles than budget alternatives while maintaining 80% capacity after 5,000 cycles.

The Durability Trinity

Through destructive testing, we identified three critical cell factors:

- Electrode Density3 - Higher nickel content boosts energy density

- Separator Quality - Ceramic-coated separators prevent dendrites

- Housing Integrity - Laser-welded casings eliminate moisture ingress

One manufacturer's "million-mile battery" prototype impressed me by surviving 15,000 cycles - equivalent to 30 years of daily use - through these innovations.

Enhanced Protection: How Storage Systems Prevent Fire and Explosion

What happens when multiple safety systems fail simultaneously? Modern batteries plan for these worst-case scenarios.

Multi-layer protection4 includes flame-retardant materials, explosion vents, and real-time gas sensors that trigger automatic shutdowns before thermal runaway occurs, reducing fire risk by 99.97% in UL-certified systems.

The Defense-in-Depth Approach

Recent UL 9540A testing revealed how protection stacks up:

- First Line: Voltage monitoring detects abnormal cell behavior

- Second Line: Coolant flow stops thermal propagation

- Final Barrier: Fireproof cabinets contain any incidents

I witnessed a dramatic test where a deliberately damaged battery module self-extinguished within 90 seconds thanks to these systems - a far cry from early battery fires that took hours to control.

Conclusion

Today's safest, longest-lasting batteries combine intelligent cooling, military-grade cells, and redundant safety systems that make catastrophic failures nearly impossible while extending usable life beyond a decade.

Find out how AI technology optimizes battery cooling, reducing degradation and improving efficiency. ↩

Learn about the advantages of Grade-A battery cells and how they contribute to longer-lasting battery performance. ↩

Understand the significance of electrode density in enhancing energy density and overall battery performance. ↩

Discover how multi-layer protection systems prevent battery failures and enhance safety in energy storage. ↩