Optimize Energy, Maximize Lifespan: Advanced Battery Pack Design for Long-Term Reliability

Struggling with battery packs that degrade too quickly? Discover how advanced design techniques can extend your product's lifespan while optimizing energy efficiency.

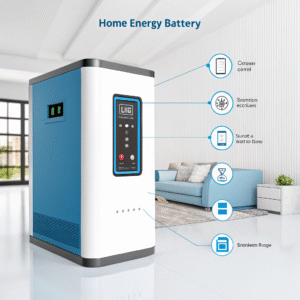

Advanced battery pack design focuses on thermal management1, cell balancing2, and robust materials to maximize energy efficiency and lifespan, ensuring long-term reliability for your applications.

The right battery pack design can mean the difference between a product that lasts years versus one that fails prematurely. Let's explore how to achieve optimal performance through intelligent engineering.

Accelerate Your Product Launch: Streamlined Battery Pack Design from Concept to Production

Frustrated by lengthy battery development cycles slowing down your product roadmap? There's a faster way to market.

Streamlined battery pack design integrates modular architectures3, standardized components, and rapid prototyping to cut development time by 40-60% while maintaining performance and safety standards.

The 3 Pillars of Rapid Battery Development

-

Modular Design Approach

- Pre-engineered battery modules that scale across product lines

- Example: Using 18650 cells in standardized configurations

-

Accelerated Testing Protocols

- Virtual simulation before physical prototyping

- Automated test equipment for rapid validation

| Development Phase | Traditional Timeline | Streamlined Approach |

|---|---|---|

| Concept Validation | 8-12 weeks | 2-3 weeks |

| Prototyping | 6-8 weeks | 1-2 weeks |

| Certification | 12-16 weeks | 6-8 weeks |

- Supply Chain Optimization

- Pre-qualified component suppliers

- Inventory management for critical parts

By implementing these strategies, companies have reduced time-to-market while maintaining quality benchmarks. The key lies in balancing speed with rigorous testing protocols.

Solving Complex Power Challenges: Tailored Battery Pack Design for Niche & High-Demand Applications

Does your application have unique power requirements that off-the-shelf solutions can't meet? Custom engineering holds the answer.

Tailored battery solutions address specialized needs through custom cell configurations4, advanced thermal systems, and application-specific BMS programming, delivering optimal performance in demanding environments.

Custom Solutions for Unique Requirements

Extreme Temperature Applications

- Phase change materials for thermal regulation

- Cold-start battery heaters (-40°C operation)

High-Vibration Environments

- Shock-absorbing mounting systems

- Conformal coating for electronics

Energy-Intensive Use Cases

- Hybrid capacitor-battery systems

- Fast-charge optimized chemistries

Case Study: A medical device company needed batteries that could withstand autoclave sterilization cycles. The solution involved:

- Specialized hermetic sealing

- Ceramic-coated connectors

- High-temperature electrolyte formulation

Navigating Regulations: Expert Battery Pack Design to Ensure Global Market Compliance

Worried about navigating the maze of international battery regulations? Compliance doesn't have to slow you down.

Global battery compliance requires understanding regional standards (UN38.3, IEC 62133, UL 2054), implementing robust documentation systems, and designing with certification requirements in mind from the outset.

Compliance Roadmap by Market

| Region | Key Standards | Testing Requirements |

|---|---|---|

| North America | UL 2054, DOT 49 CFR | Abuse testing, documentation |

| Europe | IEC 62133, CE Mark | Environmental testing |

| China | GB Standards | Local lab certification |

Pro Tip: Implement a "design for compliance5" approach by:

- Engaging certification bodies early

- Creating a compliance checklist

- Maintaining thorough material documentation

Conclusion

Advanced battery design balances performance, speed-to-market, customization, and compliance - delivering reliable power solutions that meet today's demanding requirements.

Understanding thermal management is crucial for optimizing battery performance and lifespan. ↩

Cell balancing is key to maximizing energy efficiency and prolonging battery life. ↩

Modular architectures can significantly reduce development time and enhance scalability. ↩

Custom configurations can meet specific power needs, improving overall application performance. ↩

This approach streamlines the certification process, saving time and resources. ↩