Optimize Your OPEX: Why Maintenance-Free Inverter Batteries Are a Smart Financial Move?

Struggling with rising operational costs and constant battery maintenance? There's a smarter power solution that cuts expenses while boosting reliability.

Maintenance-free inverter batteries1 reduce OPEX by eliminating service costs, downtime, and replacement expenses, delivering long-term savings with superior performance and hassle-free operation.

The financial burden of traditional battery systems goes beyond upfront costs—let’s explore how maintenance-free alternatives transform your power infrastructure into a cost-saving asset.

Zero Service Headaches: The Business Advantage of Maintenance-Free Battery Inverters

Tired of unexpected downtime and costly technician visits? Maintenance-free batteries redefine reliability.

Maintenance-free battery inverters eliminate servicing needs, reduce labor costs, and prevent operational disruptions, ensuring uninterrupted power with no ongoing upkeep expenses.

The Hidden Costs of Traditional Battery Maintenance

- Labor Expenses: Regular water topping, terminal cleaning, and voltage checks require dedicated staff time.

- Downtime Impact: Servicing schedules disrupt operations, risking productivity losses.

- Replacement Frequency: Conventional batteries degrade faster, increasing lifecycle costs.

| Factor | Traditional Battery | Maintenance-Free Battery |

|---|---|---|

| Annual Service Cost | $200–$500 | $0 |

| Expected Lifespan | 3–5 years | 5–8 years |

| Failure Risk | High (acid leaks, sulfation) | Low (sealed design) |

Pro Tip: For industries like healthcare or data centers, where uptime is critical, maintenance-free systems mitigate risks of human error during servicing.

The Smart Investment: Calculating the ROI of Maintenance-Free Battery Inverter Systems2

Is the higher upfront cost justified? The numbers reveal a compelling case.

Maintenance-free batteries offer 20–30% higher ROI over 5 years by slashing servicing fees, extending lifespan, and improving energy efficiency compared to traditional options.

Breaking Down the ROI (5-Year Analysis)

- Upfront Cost: Maintenance-free batteries cost ~15% more initially but offset this quickly.

- Savings Drivers:

- No servicing labor ($1,000–$2,500 saved).

- Fewer replacements (1 vs. 2+ for lead-acid).

- Lower energy waste (efficient discharge cycles).

- Example: A 10kVA system saves ~$3,200 net after accounting for higher purchase price.

Case Study: A telecom tower operator reduced OPEX by 22% after switching, with ROI achieved in 2.5 years.

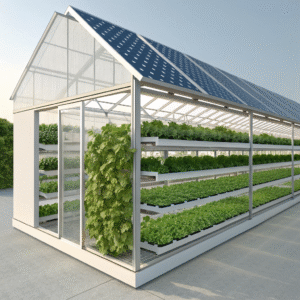

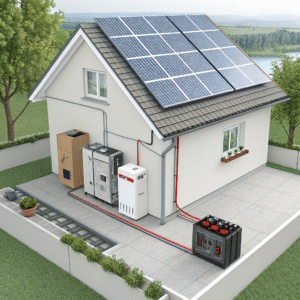

Simplify Your Infrastructure: The Next Generation of Power with Maintenance-Free Integrated Systems

Why juggle multiple components when integrated solutions streamline performance3?

Modern maintenance-free systems combine inverters and batteries with smart monitoring, reducing footprint, installation complexity, and failure points while optimizing energy use.

Key Features of Integrated Systems

- Plug-and-Play Design: No assembly or wiring expertise needed.

- AI Monitoring4: Predictive alerts for battery health via cloud apps.

- Scalability: Stackable units grow with your power needs.

Ideal For: SMEs and remote sites lacking technical staff.

Conclusion

Maintenance-free inverter batteries1 cut costs, boost reliability, and simplify operations—proving their value as a strategic OPEX solution.

Explore how maintenance-free inverter batteries can significantly reduce operational costs and enhance reliability. ↩

Discover the financial benefits and return on investment of switching to maintenance-free battery systems. ↩

Find out how integrated power solutions can enhance efficiency and reduce complexity in operations. ↩

Explore the role of AI monitoring in optimizing battery performance and ensuring reliability. ↩