Powering Your Innovation: Tailored OEM Battery Storage Solutions for Seamless Product Integration

Struggling to find battery solutions that perfectly fit your product's unique requirements? You're not alone - most manufacturers face this exact challenge when bringing new innovations to market.

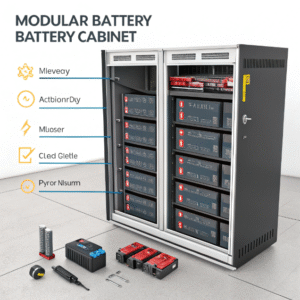

Tailored OEM battery storage solutions1 provide customized energy systems2 designed specifically for your product's form factor, performance needs, and manufacturing processes, enabling faster time-to-market and superior product performance.

The right battery solution can make or break your product's success in today's competitive marketplace. Let's explore how customized OEM battery partnerships can transform your product development process.

Build Smarter, Not Harder: Leverage OEM Battery Solutions to Accelerate Your Product Development

Why waste time reinventing the wheel when specialized battery solutions already exist for your application?

OEM battery partnerships accelerate product development3 by providing pre-engineered, tested solutions that eliminate the need for in-house battery R&D, reducing development timelines by 30-50% while ensuring optimal performance and safety.

Customization Without the Complexity

Working with an OEM battery partner gives you access to:

| Benefit | Impact |

|---|---|

| Pre-certified solutions | Faster regulatory approval |

| Modular designs | Easier product iteration |

| Scalable architectures | Simplified future upgrades |

The most successful product teams understand that battery integration shouldn't be their core focus - their innovation lies elsewhere. By leveraging an OEM partner's existing battery platforms, you gain:

- Access to specialized battery chemistries (Li-ion, LiPo, NiMH) without developing expertise

- Reduced risk through pre-validated thermal management systems4

- Faster prototyping with standard form factors that can be customized

Learn more about battery platform strategies

OEM battery solutions always require complete custom engineering. False

Most OEM partners offer modular systems that can be adapted to your needs without full custom development.

Unlock Volume Savings: Strategic OEM Battery Storage Partnerships for Cost-Effective Manufacturing

How much could your bottom line improve with optimized battery procurement?

Strategic OEM battery partnerships deliver 15-40% cost savings through volume pricing, shared engineering resources, and manufacturing efficiencies, while maintaining quality and performance standards.

The Volume Advantage

Key factors that drive cost savings:

- Economies of scale - Pooling demand across multiple customers

- Shared tooling costs - Amortizing mold and fixture expenses

- Optimized logistics - Consolidated shipping and warehousing

Cost Comparison: Custom vs. OEM Battery Solutions

| Cost Factor | Custom Solution | OEM Partnership |

|---|---|---|

| Development | $50-100k | $5-15k |

| Tooling | $30-75k | Shared cost |

| Unit Cost (10k units) | $45 | $32 |

By aligning your production forecasts with an OEM partner's manufacturing cycles, you can achieve even greater savings through:

- Just-in-time inventory programs

- Seasonal pricing advantages

- Long-term supply agreements

OEM partnerships only benefit large-volume manufacturers. False

Even mid-size production runs (1,000-5,000 units) can achieve significant savings through strategic partnerships.

Future-Proof Your Product Line: Scalable & Adaptable OEM Battery Storage for Evolving Markets

What happens when market demands outpace your current battery solution?

Scalable OEM battery architectures allow for seamless capacity upgrades, chemistry changes, and form factor evolutions, protecting your product line from obsolescence as technology and market requirements advance.

Designing for the Future

Three critical aspects of future-proof battery solutions5:

- Modular Designs - Swap individual cells or packs without full redesign

- Forward-Compatible Interfaces - Maintain same mechanical/electrical connections

- Chemistry-Agnostic Systems - Accommodate new battery technologies

Future-Proofing Checklist:

- [ ] Standardized communication protocols

- [ ] Expandable physical enclosures

- [ ] Over-provisioned thermal systems

- [ ] Software-upgradable BMS

Real-world example: A medical device manufacturer used a scalable OEM battery platform to:

- Increase runtime 40% for next-gen model

- Transition from NiMH to Li-ion chemistry

- Maintain same form factor and certifications

All with zero mechanical redesign costs.

Case study: Battery platform evolution

Future-proof designs always cost more initially. False

Smart OEM platforms build in scalability at minimal upfront cost through thoughtful architecture.

Conclusion

Strategic OEM battery partnerships deliver customized solutions, cost efficiencies, and future-ready architectures - accelerating innovation while reducing risk and development costs.

Discover how OEM battery storage solutions can enhance your product's performance and speed up development. ↩

Learn how tailored energy systems can optimize your product's design and functionality. ↩

Explore effective strategies to speed up your product development process with battery solutions. ↩

Explore the critical role of thermal management systems in ensuring battery safety and performance. ↩

Understand the significance of future-proof battery solutions in adapting to market changes. ↩