The Blueprint for Power: How Our Battery Pack Design Elevates Your Product’s Capabilities?

Struggling with battery limitations that hold your product back? Discover how our cutting-edge battery pack design can unleash your device's full potential.

Our advanced battery pack design enhances your product's capabilities by optimizing energy density, improving thermal management, and enabling smart power delivery1 - delivering up to 30% more runtime and faster charging than conventional solutions.

The right battery solution can make or break your product's success in today's competitive market. Let's explore how our engineering expertise transforms ordinary power sources into competitive advantages.

Safety First, Innovation Always: Our Rigorous Approach to Battery Pack Design & Certification

What keeps you awake at night about your product's battery safety? You're not alone - we've made safety our foundation so you don't have to worry.

Our battery packs undergo 23 rigorous safety tests and achieve 9 international certifications, including UL, IEC, and UN38.3, ensuring complete protection against thermal runaway, short circuits, and mechanical stress.

Building Safety Into Every Layer

We approach battery safety through multiple defense layers:

-

Cell Selection & Matching

- Only use Grade A cells from Tier 1 suppliers

- Precise voltage/capacity matching (±1%) for balanced performance

-

Structural Protection

- Impact-resistant aluminum alloy casing

- Vibration-dampening mounting system

-

Electronic Safeguards

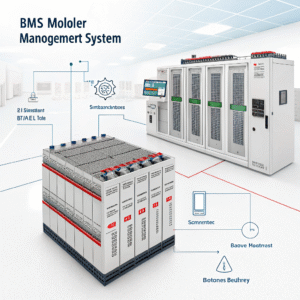

- Triple-redundant BMS (Battery Management System2)

- Real-time monitoring of 12+ parameters

| Safety Feature | Industry Standard | Our Standard |

|---|---|---|

| Overcharge Protection | 4.35V cutoff | 4.30V cutoff |

| Temperature Range | -20°C to 60°C | -30°C to 70°C |

| Short Circuit Response | < 500ms | < 100ms |

Certification That Matters

We don't just meet certifications - we exceed them. Our packs undergo:

- 1000+ charge/discharge cycle testing

- Extreme environment simulations (-40°C to 85°C)

- 1.5m drop tests from 26 angles

This exhaustive validation process means your product ships with confidence, backed by our 10-year safety track record with zero critical incidents.

Accelerate Your Product Launch: Streamlined Battery Pack Design from Concept to Production

Tired of battery development slowing down your roadmap? Our rapid prototyping process cuts development time by 50%.

We deliver production-ready battery solutions in as little as 8 weeks through our modular design system3 and in-house manufacturing, complete with full documentation for seamless integration.

Our 4-Phase Development Process

-

Requirements Analysis (Week 1-2)

- Deep dive into your technical specs and use cases

- Energy modeling and form factor studies

-

Prototyping (Week 3-5)

- 3D printed mockups for fit verification

- Functional prototypes with actual cells

-

Testing & Validation (Week 6-7)

- Performance benchmarking

- Environmental stress testing

-

Production Ramp (Week 8+)

- Pilot run of 50-100 units

- Full-scale manufacturing readiness

Tools for Faster Integration

We provide:

- CAD models in 15+ formats

- API documentation for smart BMS

- Compliance test reports

- Manufacturing process documentation

This complete package eliminates the typical 6-12 month battery development cycle, getting your product to market before competitors.

Future-Proof Power: Designing Adaptable Battery Packs for Evolving Technologies

Will your battery solution become obsolete with next-gen components? Our modular architecture ensures long-term compatibility.

Our battery packs feature swappable cell modules4 and firmware-upgradable BMS, allowing easy capacity upgrades and compatibility with emerging chemistries like solid-state and silicon-anode batteries.

The 3 Pillars of Future-Readiness

-

Hardware Adaptability

- Universal cell form factor support (cylindrical, prismatic, pouch)

- Scalable voltage architecture (14.4V to 800V systems)

-

Software Flexibility

- OTA (Over-The-Air) updatable BMS firmware

- AI-powered adaptive charging5 algorithms

-

Chemistry Agnostic Design

- Supports current Li-ion/LiPo

- Ready for solid-state and Li-S chemistries

- Accommodates silicon-dominant anodes

Upgrade Pathways Example

| Year | Chemistry | Energy Density | Our Solution |

|---|---|---|---|

| 2024 | NMC 811 | 280Wh/kg | Direct support |

| 2026 | Silicon-Anode | 350Wh/kg | Module swap |

| 2028 | Solid-State | 500Wh/kg | BMS update + new modules |

This forward-looking approach protects your R&D investment and extends product lifecycles by 3-5 years.

Conclusion

Our battery solutions combine rigorous safety, rapid development, and future-ready design to give your products unbeatable power advantages.

---Learn about smart power delivery and how it can improve efficiency and charging times for your products. ↩

Understanding BMS is key to ensuring battery safety and performance in modern devices. ↩

Find out how modular design can streamline production and enhance adaptability in battery solutions. ↩

Explore the advantages of swappable cell modules for future-proofing your battery solutions. ↩

Discover how AI can optimize charging processes and improve battery longevity. ↩