What Your Competitors Get Wrong About Bifacial Gain (And How You Can Use It to Win More Bids)

Bifacial panels promise extra energy, but most installers misunderstand their true potential. This confusion creates a massive opportunity for you.

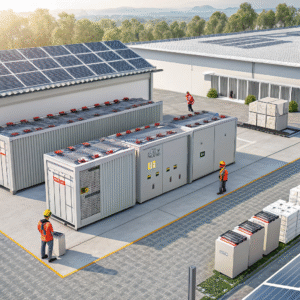

Bifacial gain1 refers to the additional energy production from sunlight reflected onto the backside of solar panels. Proper installation and surface selection can increase energy output by 5-30% compared to monofacial panels.

While competitors focus on technical specs, you can focus on real-world performance. Let's explore how to leverage bifacial technology to create unbeatable value propositions for your customers.

How to Explain the Value of a Premium Panel to Your Homeowner Customer Without Using Technical Jargon?

Homeowners' eyes glaze over when you mention "PERC cells" or "PID resistance." How do you make premium panels compelling?

Premium panels work better in real-world conditions, generating more electricity from the same sunlight. This means faster payback and better performance during cloudy days and partial shading.

Making Technology Relatable

Think of premium panels like a high-performance car versus a basic sedan. Both get you from point A to point B, but the premium option handles better in tough conditions and lasts longer. Here's how to translate technical advantages into customer benefits:

| Technical Feature | Customer Benefit | Simple Explanation |

|---|---|---|

| Bifacial Design | More Energy | "Catches extra sunlight bouncing off your roof" |

| Better Durability | Longer Warranty | "Built to withstand harsh weather for decades" |

| Higher Efficiency | Smaller Footprint | "Generates the same power with fewer panels" |

The key is focusing on outcomes, not specifications. Instead of "monocrystalline PERC technology," say "panels that squeeze more electricity from every ray of sunlight." Rather than "PID resistance," explain "technology that prevents gradual power loss over time."

Premium panels2 shine in imperfect conditions - early mornings, late afternoons, and cloudy days when standard panels underperform. This consistent performance translates to more reliable energy production throughout the day and year.

Why Does the Backsheet Matter? How a Small Detail Can Lead to Catastrophic Project Failure?

That thin plastic layer on the back of panels seems insignificant until it fails. Then you're facing callbacks, warranty claims, and angry customers.

The backsheet protects solar cells from moisture, UV damage, and electrical hazards. A compromised backsheet can cause power degradation, safety issues, and complete system failure within years instead of decades.

The Hidden Importance of Backsheet Quality

I've seen projects where backsheet failure turned profitable installations into financial nightmares. The backsheet is essentially the panel's weatherproof jacket - when it fails, everything inside is exposed to the elements.

Common Backsheet Failure Modes:

- Cracking and Delamination: Allows moisture ingress leading to corrosion

- UV Degradation: Causes yellowing and brittleness over time

- Electrical Insulation Failure: Creates safety hazards and fire risks

Material Comparison:

| Backsheet Type | Durability | Cost | Best Use |

|---|---|---|---|

| TPT/Tedlar | Excellent | High | Commercial/Long-term projects |

| PPE/PPE | Good | Medium | Residential standard |

| PET/PET | Basic | Low | Budget installations |

Premium backsheets use multilayer construction with materials like Tedlar that resist environmental stress. Budget panels often use single-layer PET that degrades faster. The extra cost for quality backsheets is insurance against future headaches.

What to Do When a Panel Arrives Damaged: A Transparent Look at Our DOA Policy and How We Protect Your Project Timeline?

Nothing derails a solar installation faster than discovering damaged panels on site. Your competitors panic - you have a plan.

Immediately document damage with photos, contact the supplier within 24 hours, and use our pre-approved replacement process. We maintain buffer stock specifically for these situations to keep your projects on schedule.

Streamlining the Damage Resolution Process

Having handled hundreds of damaged panel cases, I've developed a system that turns potential disasters into minor inconveniences. Here's our proven approach:

Step-by-Step Damage Protocol:

- Document Everything: Take clear photos of packaging and panel damage before moving from delivery location

- Immediate Notification: Contact supplier with documentation within 24-hour window

- Parallel Processing: Continue installation with undamaged panels while replacement is arranged

- Buffer Inventory: We keep emergency stock for quick replacements

- Project Continuity: Never let one damaged panel stop entire project progress

Common Damage Types and Solutions:

| Damage Type | Action Required | Timeline Impact |

|---|---|---|

| Minor Frame Scratch | Customer approval or use on less visible area | None |

| Cracked Glass | Full replacement | 1-3 days with buffer stock |

| Electrical Damage | Immediate replacement | 1-3 days with buffer stock |

Our secret weapon? Maintaining a small buffer inventory of common panel models. This allows us to swap damaged units immediately and process the warranty claim separately. Your customers never experience the delay.

Conclusion

Understanding bifacial technology's real advantages and having robust installation protocols positions you as the expert who delivers results, not just panels.